NEWS

13 NOVEMBER, 2020 -

13 NOVEMBER, 2020 -

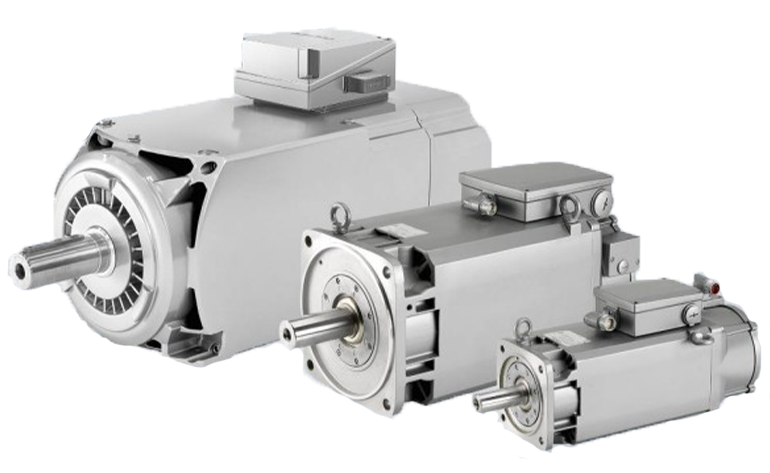

Servo and Spindle motors are motors used in the production of many sectors. Servo or Spindle Motor failures cause production to slow down or even come to a standstill, resulting in loss of time and cost for the company.

At the beginning of the most common servo motor and spindle motor failures are the errors that require spare part replacement such as encoder error, resolver error, bearing locking. There are many reasons for the occurrence of these malfunctions, such as not performing annual maintenance, the environment in which the engine operates, operating power, speed, water, oil, liquid and foreign substances that may enter the engine. These failures may cause wear and deterioration in spare parts of servo motors and spindle motors. For these reasons, not using original spare parts can cause irreversible damage to the engines and even scrap the engine.

So how does the use of Original Spare Parts benefit the engines?

The use of original spare parts is a major factor in the performance of servo motors and spindle motors. Extends the service life of engines. It provides more accurate fault diagnosis and guaranteed maintenance depending on the maintenance at the original service. In this ratio, production does not interrupt, it does not cause cost and time loss.